Failure of indoor (evaporator) coils in the form of refrigerant leaks is an issue in the HVAC industry. Although the occurrence of these failures is very low nationwide, unexplainable failures occur more frequently in some geographic areas. Failures are typically characterized by leaks that form in the finned area of the coil. This usually occurs after one to four years of installation and use.

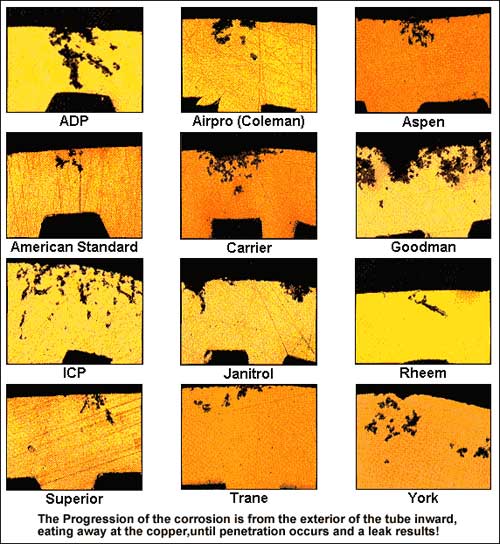

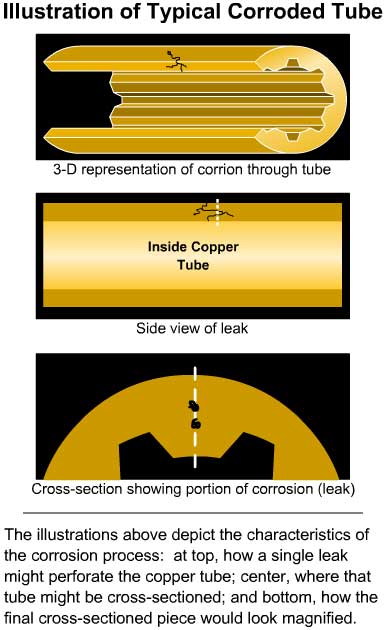

The problem exists industry-wide, on any coil brand. The corrosion is from the exterior of the tube inward, eating away the copper, until a leak results.

There are many reasons that a coil might leak such as mechanical damage, manufacturing defect in components, improper brazing, and corrosion. There are several different corrosion mechanisms that can affect copper tubing.

A major Industry Research Report presented by Carrier concluded that two forms of corrosion are found in indoor coils. These are general pitting and formicary corrosion.

According to the report, general pitting is commonly caused by aggressive attack on the copper tube and is characterized by large pits resembling bite marks. These can often be observed with the human eye. Chlorides are the most common cause of general pitting corrosion.

Formicary corrosion, on the other hand, appears as multiple tiny pinhole leaks at the surface of the copper tube. These are not visible to the human eye. Upon microscopic examination, the formicary corrosion pits show networks of interconnecting tunnels through the copper wall. This type of corrosion is generally caused by organic acids.

There are many sources of organic acids in both the coil application and the coil production environment. The most common organic acids are formic and acetic acids. Formaldehyde can be converted to formic acid and then to formate in moisture. Acetic acid is converted to acetate in water. All of these compounds are aggressive to copper, resulting in the ant's nest corrosion footprint.

Common household sources that may contain formic acid, formaldehyde, of formate include:

There are three conditions required for formicary corrosion to occur.

Environmental Factors

Many manufactures are experiencing identical failures indicating that external environmental factors are part of the cause. Each manufacture has a different assembly process and there are multiple sources of raw materials; however, a chemical analysis of materials used in manufacturing can identify the presence of corrosive agents. Generally, these have been either eliminated, replaced with less corrosive compounds, or thoroughly removed prior to the coil being installed in production units.

As stated above, the potential sources of agents that can cause pitting corrosion in indoor coils are numerous, and there is increasing evidence to show the home environment as the primary contributor to coil corrosion. The trend in home construction is to improve energy efficiency by making homes "tighter." The direct result is higher concentration levels of indoor contaminants.

A recent study, conducted by the Lawrence Berkeley National Laboratory with support of the U. S. Department of Energy, measured the volatile organic compound concentrations and emission rates in new manufactured and site-built houses. The study concluded that many materials such as plywood, engineered wood products, latex paint, and sheet vinyl used in the construction of new houses are major sources of VOCs, such as formaldehyde. Concentrations of acetic acid, formaldehyde, and acetaldehyde inside homes in this study were significantly higher than levels measured outside the homes. The elevated concentration was seen to persist for at least nine months. What is more, the measured levels of acetic acid actually increased during the study.

Another study investigated the emission rates of wood and engineered wood products in test chambers. The results of this testing support the theory that these products are also a source of organic acids, especially formic and acetic acids. In addition to building materials furniture is another source of volatile organic compounds in the indoor environment, much of it being made from engineered wood products such as particle board.

Condensate Analysis

In another study, analysis of condensate from units where coils had failed confirm the presence of significant levels of formate and acetate in the household environments. The condensate samples were collected prior to and immediately after the coils were replaced. A follow-up assessments was done a month later at some sites.

The levels of corrosive agents were elevated prior to coil replacement. Condensate drawn immediately from the new coil showed dramatically decreased levels. After a short period of operation, the levels returned to elevated levels. This test confirms that the corrosive agents are not tied to the replacement coils since the condensate samples drawn directly off the new coils show decreased levels of acetate and formate. After the replacement coil has been operating for a period of time, the levels of these agents once again reflect the operating environment of the coil.

Conclusions

There is increasing evidence that the primary cause of indoor coil leak failure is corrosive agents present in the household environment. Significant levels of these agents, known to cause these failures, have been quantified in indoor condensate. Decreased home ventilation rates coupled with increased use of engineered products in home construction contribute to elevated levels of indoor contaminants which can lead to coil corrosion and failure.

We Offer Financing